- Home

- About Us

- Products

- Services

- Recommendation

- Industries

- Resource

- Order Center

- Contact Us

Water is vital to people's health, industrial production, and ecological environment. With the shortage of water resources in the world and the deterioration of water quality, the effective and safe treatment of water has become a major issue faced by the public. Reverse osmosis (RO) is a water treatment technology with high efficiency and environmental friendliness and is widely used in industrial production, commercial water supply, and household water treatment systems. In this article, we will introduce the basic principles of reverse osmosis technology, explain the operating mechanism in detail, and elaborate on the important role of reverse osmosis-specific chemicals.

Reverse osmosis (RO) is a water purification technology that separates water molecules and other dissolved solutes, such as salts, bacteria, organic molecules, and other impurities, by a semi-permeable membrane under pressure. It is a molecular-level filtration technology different from traditional filtration technology. The removal rate of RO technology is more than 95%, so it is widely used in water purification.

The reverse osmosis system is an efficient purification system first applied to the desalination of seawater. It has been used not only in the desalination of seawater and groundwater but also in industrial pure water production, municipal wastewater reuse, food processing industry, medical use, household water purification, and other fields.

The reverse osmosis (RO) is a water purification technology that can effectively remove salts, organics, microorganisms, and other impurities dissolved in water by physical filtration technology.

Before the water enters the reverse osmosis membrane, the pre-treatment process is generally required. This is to protect the RO membrane and prolong its service life.

The pretreated water enters the core part of the RO system, which is the RO membrane. The operating pressure is generally 2–17 bar for freshwater and brackish water treatment and 40–82 bar for seawater treatment.

Figure1. Reverse osmosis principle

Figure1. Reverse osmosis principle

Although the water after being filtered by the RO membrane is very pure, post-treatment is generally required to further improve the water quality.

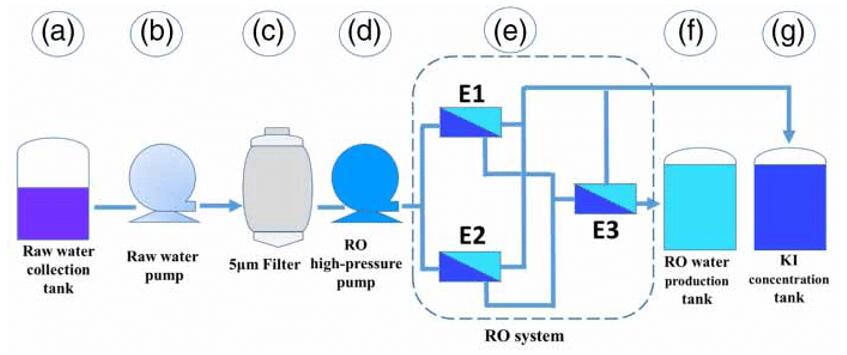

Figure 2. RO system arrangement flowchart.

Figure 2. RO system arrangement flowchart.

Table 1. RO system unit

| Item | Unit | Parameter |

|---|---|---|

| A | Raw water collection tank | 10 m3 FRP |

| B | Raw water pump | 25 m3/h × 3 kg/cm2 |

| C | 5 μm filter | 30 in2 × 12 pvc pp |

| D | RO high-pressure pump | 25 m3 /h × 12 kg/cm2 |

| E | RO system unit | |

| E1 | 2:1 housing pipe arrange | |

| E2 | 5 unit LFC3-LD/1 set outside pipe | |

| E3 | 0.7–1 m3 /1 unit | |

| F | RO water production tank | 10 m3 FRP |

| G | KI concentration tank | 10 m3 FRP |

The main problems encountered in the operation of reverse osmosis (RO) systems include membrane scaling, membrane fouling, biofouling, abnormal pressure, abnormal flow, and other conditions. These conditions not only affect the system's efficiency and life but also increase operating costs and maintenance frequency. The following are the common problems of the system and the corresponding solutions.

Membrane Scaling

Membrane scaling is a process in which sparingly soluble salts such as calcium carbonate, calcium sulfate, and silica scale are deposited on the membrane surface or in the concentrate flow channel. The scaling process generally occurs when the water in the system is sufficiently concentrated and the pore is blocked and has low water flux. The main reason for scaling is that the hardness and alkalinity of the feed water are high. This problem often occurs during seawater desalination treatment.

Membrane Fouling

Membrane fouling is a phenomenon in which inorganic substances, organic substances, bacteria, colloids, and other contaminants attach to the membrane surface and form a layer on the surface of the membrane, resulting in a reduction in flux and deterioration of membrane performance. Membrane fouling not only affects the quality of permeate but also increases the resistance of the system and the amount of energy consumed. According to the type of pollutants that cause membrane fouling, it can be divided into inorganic fouling, organic fouling, colloidal fouling, and biofouling.

Membrane Biofouling

Biofouling is a kind of contamination that causes microorganisms such as bacteria and algae to attach to the membrane surface and proliferate to form biofilms on the surface of the membrane. Biofouling has a very important influence on the system. It not only reduces membrane flux and causes salt passage to increase but also occurs in the early stage of the operation of the RO system. Once the biofilm is formed, it is very difficult to remove. Studies have found that even a short period of biofouling can severely impact system performance.

Abnormal Pressure and Flow

If the membrane elements are blocked or the pipes are faulty, the RO system will also have abnormal high pressure and low permeate flow. This will not only reduce the water production efficiency of the system but also easily damage the membrane elements.

For the above issues, various chemicals can be used for RO systems to achieve optimal operating conditions and extend the life of the system. The following are some of the commonly used RO chemicals and their functions.

RO Antiscalants

RO antiscalants are a kind of chemical that prevents calcium carbonate, calcium sulfate, silica scale and other salts from depositing and precipitating in the system. Antiscalants play a role by chelating calcium, magnesium, barium ions and other ions to increase the solubility of sparingly soluble salts and inhibit crystal growth and precipitation to achieve antiscalant effect. The antiscalant mechanism includes chelation, lattice distortion and dispersion effect and so on. Its function is to reduce the possibility of scale forming on the membrane surface.

| Catalog | Product Name | Classification | Order |

|---|---|---|---|

| ECO-RO-001 | Anti-scaling Agent for RO Membranes (Acidic) | Antiscalants | Inquiry |

| ECO-RO-002 | Anti-scaling Agent for RO Membranes (Alkaline) | Antiscalants | Inquiry |

| ECO-RO-003 | Special Antiscalant for Reclaimed Water | Antiscalants | Inquiry |

| ECO-RO-004 | Antiscalant for Seawater Desalination | Antiscalants | Inquiry |

| ECO-RO-005 | Anti-scaling Agent for RO Membranes (Phosphorous-free) | Antiscalants | Inquiry |

| ECO-RO-006 | Anti-scaling Agent for DTRO Membranes | Antiscalants | Inquiry |

RO Membrane Cleaners

The membrane cleaner is used for the periodic cleaning of the membrane surface. It can clean the various contaminants attached to the membrane surface and restore the permeability. The commonly used membrane cleaners are acidic solutions such as hydrochloric acid and phosphoric acid, alkaline solutions such as sodium hydroxide, and sodium dodecyl sulfate. Acidic cleaners are mostly used for inorganic scale removal, and alkaline cleaners are mostly used to remove organic and colloidal fouling. In addition, the cleaner has a cleaning effect by saponifying lipids, dissolving proteins, and changing the pH value.

| Catalog | Product Name | Classification | Order |

|---|---|---|---|

| ECO-RO-008 | Cleaning Agent for RO Membranes (Acidic) | Cleaning Agents | Inquiry |

| ECO-RO-009 | Cleaning Agent for RO Membranes (Alkaline) | Cleaning Agents | Inquiry |

Biocides

Biocide is used to control the growth of microorganisms in the system. Biocides can be classified into oxidizing and non-oxidizing biocides according to their working mechanism. Oxidizing biocides (such as chlorine) are usually used in the pre-treatment process. Non-oxidizing biocides (such as organic sulfur and bromine) are more suitable for deep treatment. The application of biocides can effectively reduce the attachment of microorganisms on the membrane surface, thus reducing the risk of biofouling.

| Catalog | Product Name | Classification | Order |

|---|---|---|---|

| ECO-RO-007 | Biocidal Agent for RO Membranes (Non-oxidative) | Biocides | Inquiry |

| ECO-RO-012 | Biocidal Agent for RO Membranes (Chlorine-based Oxidative) | Biocides | Inquiry |

| ECO-RO-013 | Biocidal Agent for RO Membranes (Bromine-based Non-oxidative) | Biocides | Inquiry |

pH Adjusters

RO pH adjusters are used to optimize the operating conditions of the RO system so that the membrane is always in the ideal operating pH value. For example, adding a certain acid (such as sulfuric acid or hydrochloric acid) to the feed water can reduce the pH value of the water to increase the solubility of calcium carbonate, so that it will not scale in the system. In addition, the pH adjuster can also improve the effectiveness of the cleaner to make the cleaning process more smooth.

| Catalog | Product Name | Classification | Order |

|---|---|---|---|

| ECO-RO-010 | Flocculating Agent for RO Membranes | Others | Inquiry |

| ECO-RO-011 | Reducing Agent for RO Membranes | Others | Inquiry |

Reverse osmosis technology has become an indispensable member in many industries due to its excellent purification performance. Proper selection and use of chemical additives are especially important to ensure the continuous and efficient operation of the system. We are always here to help you provide reliable and professional RO chemical solutions to make your water treatment system cleaner, more efficient, and longer lasting.

Q1: What is the main purpose of reverse osmosis?

A: It is mainly used to remove dissolved salts, organic substances, bacteria, and other contaminants from water to obtain high-purity or purified water.

Q2: What chemicals are commonly used in reverse osmosis systems?

A: Common chemicals include antiscalants, membrane cleaners, biocides, and pH adjusters.

Q3: How often should RO membranes be cleaned?

A: It depends on the quality of water and the operating conditions. Generally, it is cleaned every 3-12 months or according to the monitoring of the pressure difference and permeate flow.

Q4: Does the use of chemical agents help improve system performance?

A: Absolutely. Proper chemical agents can not only improve water quality but also extend membrane life and reduce operating costs.

Reference

Privacy Policy | Cookie Policy | Copyright © 2025 Alfa Chemistry. All rights reserved.

Back to top