- Home

- About Us

- Products

- Services

- Recommendation

- Industries

- Resource

- Order Center

- Contact Us

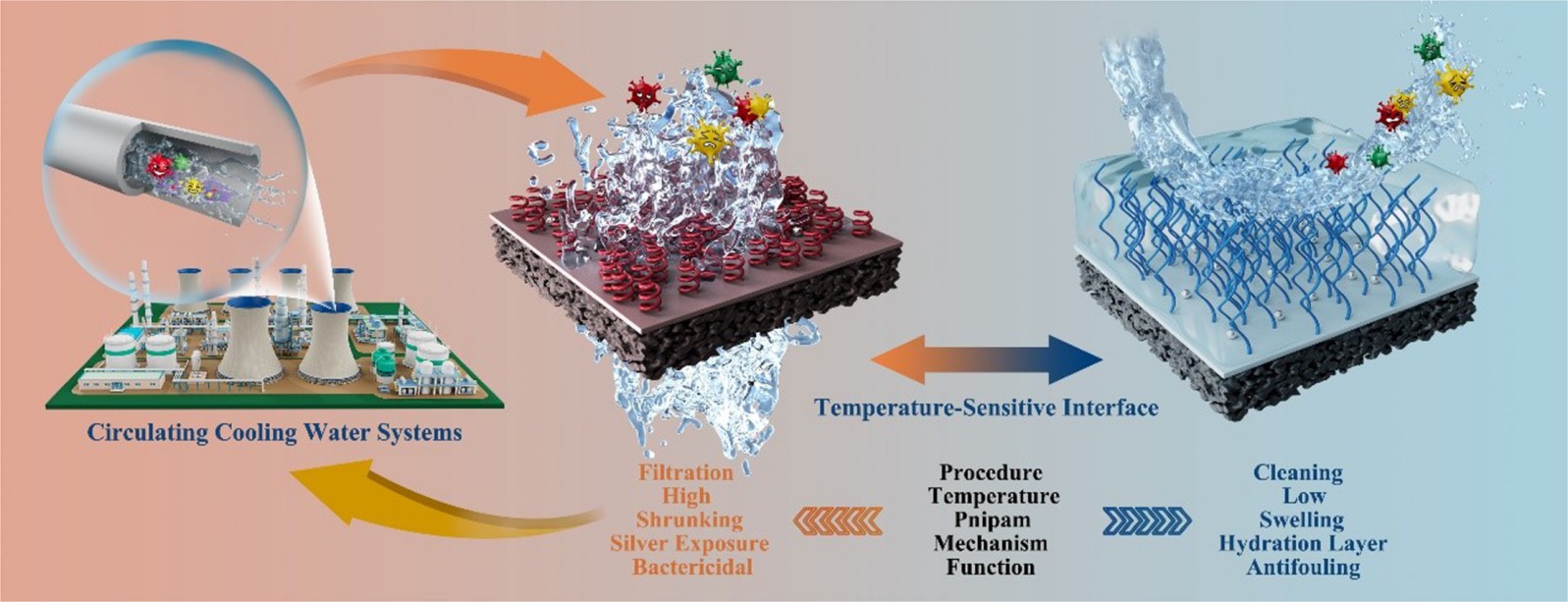

The process of circulating water treatment involves purifying and managing circulating cooling water by implementing physical, chemical, or biological methods to support efficient use in industrial operations including power plants. Circulating water treatment aims to eliminate water impurities while protecting equipment from corrosion and scaling to prolong its lifespan and minimize water usage. Power plants use a significant amount of cooling water in their circulating water systems which consumes 80% of pure water usage making circulating water treatment vital for water resource conservation and cost reduction.

Cooling towers serve as essential elements within the circulating water system. The primary task of these systems involves cooling circulating water by utilizing evaporative processes. Cooling towers fall into two categories: natural draft towers and mechanical draft towers. Natural draft cooling towers depend on wind to cool water whereas mechanical draft cooling towers utilize fans to enhance ventilation. The circulating water system typically includes cooling towers which release heat from heat exchangers into the atmosphere.

The circulating water system depends heavily on the functionality of heat exchangers as essential components. The circulating water system absorbs heat produced by steam and engine sources through heat exchangers. The typical construction for heat exchangers involves carbon steel pipes and copper tubes and some designs use synthetic polymer shell structures. The equipment finds application in steam condensation processes at power plants and serves as cooling systems for boiler feedwater pumps and turbochargers.

The operation of the water circulation system depends on both pumps and piping to move water effectively throughout the system. Circulating water pumps must produce enough pressure to allow water to flow at the necessary speed. Pump designs should fulfill the requirements for maximum cooling water flow and address the resistance present in the piping system. The piping system requires effective sealing and corrosion protection to avoid leakage and contamination problems.

Power plants must preserve high-quality circulating water because these reasons demonstrate its importance.

Excessive impurities in circulating water including microorganisms, sediments, and corrosion products can result in decreased heat exchanger efficiency and higher energy consumption.

A combination of chemical treatments and filtration systems to eliminate corrosive materials and deposits leads to extended equipment service life.

Circulating water treatment processes make wastewater recovery possible which diminishes fresh water demand.

Efficient circulating water treatment methods reduce pollution from wastewater release while promoting sustainable development initiatives.

The essential function of circulating water treatment systems supports industrial production operations especially in sectors that consume large amounts of water such as power plants. System components configuration optimization together with water quality management leads to improved energy efficiency and environmental advantages.

Cooling systems maintain their efficiency through the use of circulating water treatment chemicals which keep them clean. These chemicals prevent corrosion while controlling scaling and microbial growth to lengthen equipment lifespan and reduce system energy needs while maintaining safe operations. The chemical group that protects cooling systems includes corrosion inhibitors, scale inhibitors, biocides, and pH adjusters which each possess unique functions and action mechanisms.

Source: https://eco.alfa-chemistry.com/circulating-water-treatment.html

List of Circulating Water Treatment Chemicals

Corrosion inhibitors serve to protect metal surfaces from corrosion damage. Metal protection from corrosion uses common inhibitors including inorganic substances like chromates, nitrites and molybdates along with organic substances such as polycarboxylates and phosphates. The functionality of these agents relies on their ability to create protective or precipitate coatings on metal surfaces.

Scale inhibitors prevent the formation of mineral deposits (scaling) in water caused by substances including calcium and magnesium. Corrosion inhibitors include both organic substances like polycarboxylates and inorganic compounds such as organophosphates which contain EDTA and HEDP. The adsorption of these chemicals onto mineral crystals results in prevention of their aggregation and precipitation.

In cooling systems biocides and algaecides manage the proliferation of bacteria, algae, and fungi. Chlorides and bromides represent frequently used biocides alongside various oxidizing compounds. These substances work through either breaking down microbial cell walls and/or halting their metabolic processes.

Cooling water requires pH adjusters to control its acid-base balance because improper pH levels lead to corrosion or scaling. Sodium bicarbonate, sodium hydroxide and sulfuric acid serve as regular pH adjusters. Buffers maintain pH stability which creates a consistent chemical environment despite changing conditions.

1. Specific plant requirements

Each facility requires different water treatment chemicals to meet specific operational needs. Industrial applications demand specialized chemicals for corrosion prevention and microbial growth control along with sediment formation inhibition whereas municipal systems primarily use chemicals for disinfection and purification to maintain water safety. High-quality water treatment chemicals are essential for commercial facilities like hotels and healthcare centers to ensure they fulfill customer expectations regarding water quality.

2. Water quality and system conditions

The quality of water serves as a fundamental criterion for choosing appropriate treatment chemicals. The identification of specific pollutants that require removal depends on analyzing both the type and concentration of contaminants found in the water source. The presence of heavy metals or bacteria requires the use of specific coagulants or disinfectants. The effectiveness and selection of chemicals to treat water depend on the pH level of water as well as its temperature and chemical makeup.

3. Environmental impact

Choosing environmentally friendly chemicals is crucial. Environmental protection requires selecting chemicals that break down naturally and have minimal toxicity. Simultaneously observe local regulations to prevent pollution from incorrect chemical applications.

1. Follow proper dosage and application guidelines

Adhere to the manufacturer's dosage guidelines for accuracy and modify dosages to match water quality variations. Excessive chemical dosing results in greater expenses and environmental damage while insufficient dosing lowers treatment performance.

2. Regularly test water quality

Assess treatment efficacy through pH, turbidity, and microbial content measurements and modify chemical dosages according to findings.

3. Choose chemically compatible products

Confirm the chemicals you choose work well with your existing water treatment system so you avoid harmful chemical interactions or damage to your system.

4. Consult professional advice

Water treatment professionals and suppliers should be consulted when selecting chemicals to ensure compatibility with specific requirements and adherence to established best practices.

Reference

Privacy Policy | Cookie Policy | Copyright © 2025 Alfa Chemistry. All rights reserved.

Back to top